Naumes Custom Crush and Fermentation will support fast-growing industry

Medford, Ore. – July 2, 2015 – Naumes Crush and Fermentation (www.naumescf.com) is Southern Oregon’s newest and most modern wine processing facility. The 23,000-s.f. structure, designed to be easily expanded, is set to open August 1.

Located at 1311 N. Central Ave. near downtown Medford, Naumes Crush will provide full-service winemaking, lab analysis, cold storage and support services to growers and wineries throughout the region.

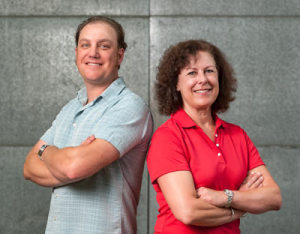

“Southern Oregon needed more custom crush capacity and we see vast potential here,” said Chief Operating Officer Laura Naumes. “Clients will use us to produce many types of wine according to their exact specifications.”

Growing fruit in Oregon for 113 years, the Naumes family is a leading producer of pears, apples, cherries and specialty fruit in the Pacific Northwest and California. Naumes Inc. also has 70 acres of its 2,000-acre holdings in the Rogue Valley planted to premium wine grapes and plans to add much more. “Custom crush is a logical extension of our family’s long agricultural heritage,” added Naumes.

Naumes Crush can handle a wide range of grape varieties and winemaking styles. The secure, ultra-sanitary facility is large enough to accommodate all custom crush needs, yet small enough to guarantee personal attention. Laura Naumes estimates the facility will process up to 200 tons of grapes this year, ultimately rising to 500+ tons.

Chris Graves is Naumes Crush’s first winemaker. A graduate of the UC Davis Viticulture & Enology Program, he has extensive knowledge of wine chemistry and analysis, understands modern winemaking thoroughly, and has custom crush experience. Previously, he served as assistant winemaker at Wente Vineyards in Livermore, Calif., then winemaker for Wente’s “Cal-Ital” winery, Tamás Estates, before launching two of his own businesses, Ruby Hill Winery and Rubino Estates Winery.

“Naumes Crush is committed to expanding the sophistication and success of Southern Oregon wine,” explained Graves. “We’re the ‘uncustomary custom crusher’ and will be constantly incorporating new best practices in winemaking and business operations, helping take wines made here to the next level.”

Most clients will be Rogue Valley or Umpqua Valley vineyard owners, smaller wineries and individuals crushing between two and 50 tons annually. A modern onsite lab will perform many high-end quality control tests and procedures. And staff can help clients closely monitor the chemistry of their wines throughout fermentation and barrel aging.

Designed in part by Willamette Valley consulting winemaker Robert Brittan, Naumes Crush is state-of-the-art. Advanced equipment – including optical sorting and hand sorting tables, 30+ open and closed top stainless steel-jacketed fermenters (2- to 10-ton capacity), gravity transfers, optional open or closed membrane pressing, and more – was sourced from leading suppliers from around the world.

Naumes Crush has nearly 20,000-s.f. of secure, temperature-controlled space to age or store finished wines. A fully automated temperature control system will provide maximum fermentation management. The facility also has extensive cold storage areas for harvested grapes (unique in Southern Oregon) and for cold soaking onsite.

“We’ve invested heavily in advanced information technology for data monitoring, management and reporting,” said Graves. “Everything in this business is organized to produce client wine that customers will love.”

Laura Naumes is also vice president of parent company Naumes, Inc. She leads an experienced management team at Naumes Crush, serves on several ag industry-related boards, and is a member of the Oregon State University Board of Trustees. A past member of the Federal Reserve Bank of San Francisco Advisory Council, Naumes is on the boards of the Rogue Valley Family YMCA and Asante Health System Foundation.

For more information, visit www.naumescf.com or call (541) 608-1721.

Featured image above: COO Laura Naumes and Winemaker Chris Graves (right) look over plans for Naumes Crush and Fermentation with Kyle White, project manager.